Raised Access Floors

What are Raised Access Floors?

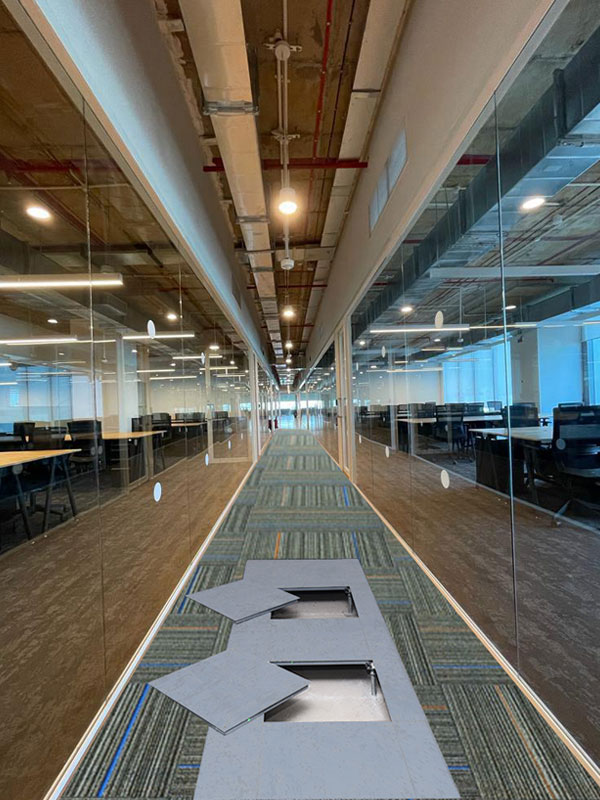

Raised Access Floors is a Flooring system that creates an elevated platform above the buildings concrete slab (often called the subfloor).

This elevation is designed to create a hidden void/cavity between the “raised floor” and the subfloor, typically used for the routing of “underfloor services” – electrical, network & data, utility to even air distribution and WLD systems depending on the needs of the end-user.

The ability to “access” the cavity and further reconfigure systems including the raised floor itself, are features unique to RAFs.

What are the typical components of a Raised Access Floor?

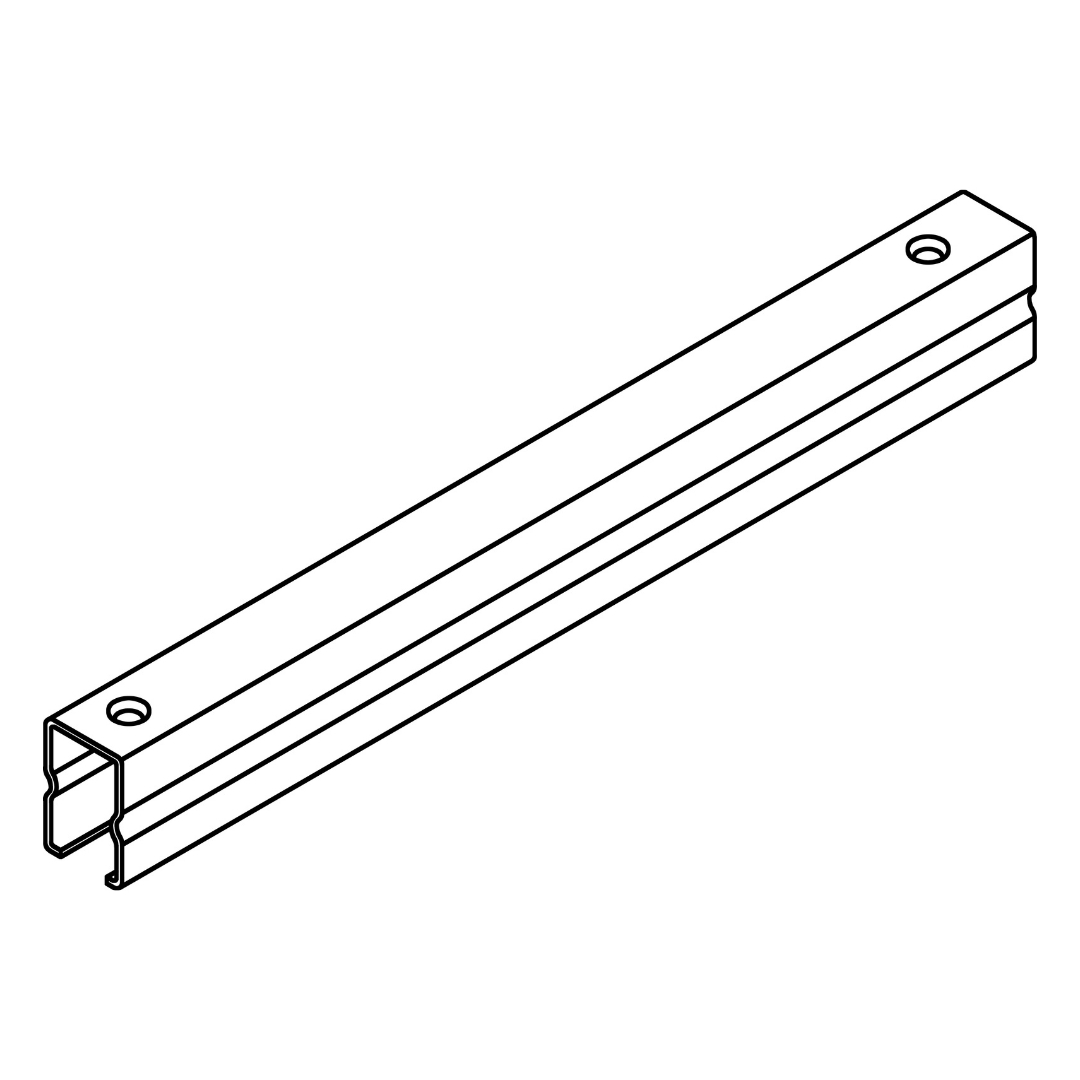

Fundamentally, RAF systems are comprised of panels that rest above a grid of pedestals, that may be further supported at the edges by stringers depending on the type of panel installed. The stringers and pedestals are itself classified as part of the understructure of an RAF system.

Panel

This is the horizontal load-bearing element of a raised floor, standardized at 600mm x 600mm in dimension. Panels are classified by various segments: namely Panel Type, Panel Surface Finish, Panel Grade.

Panel Type

The technical specification addresses the outer and inner components of a panel. Examples of panel classes include Steel Cementitious (Steel Panel with cementitious infill), Calcium Sulphate Core (Steel Panel with Calcium Sulphate infill), and Woodcore.

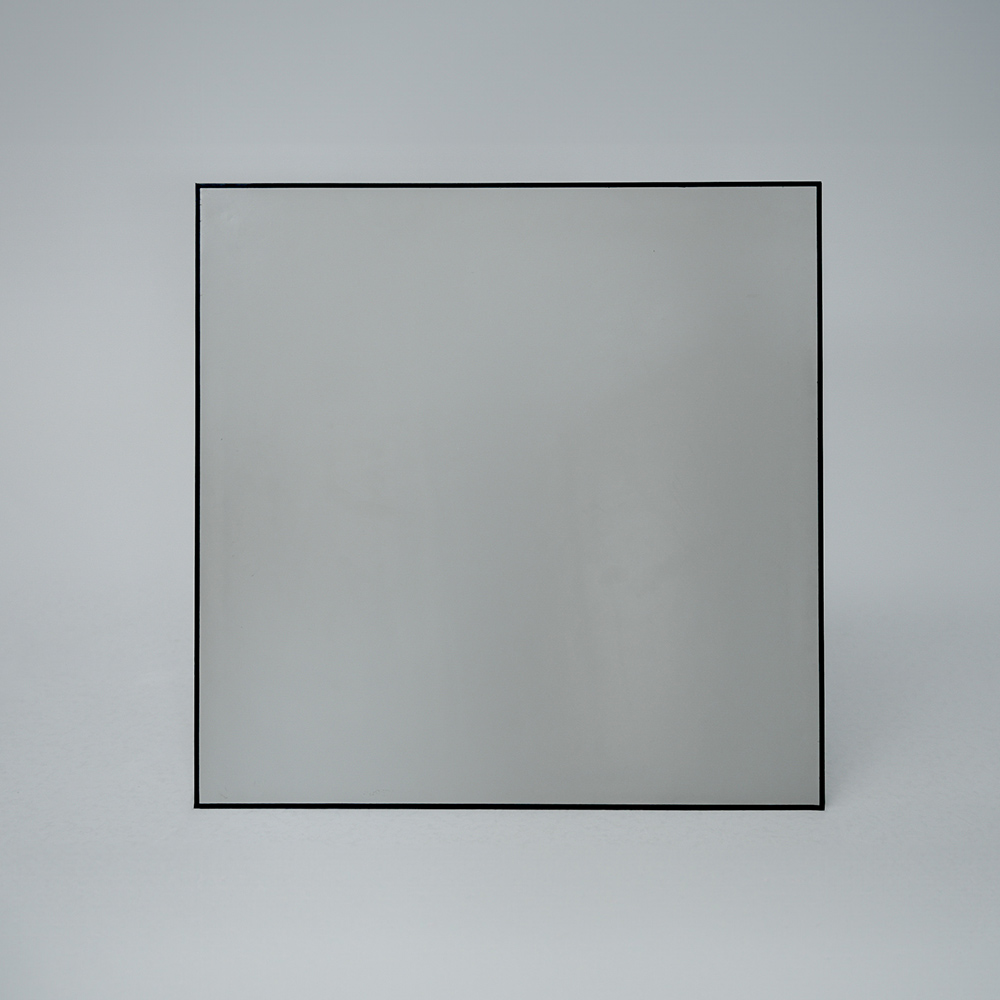

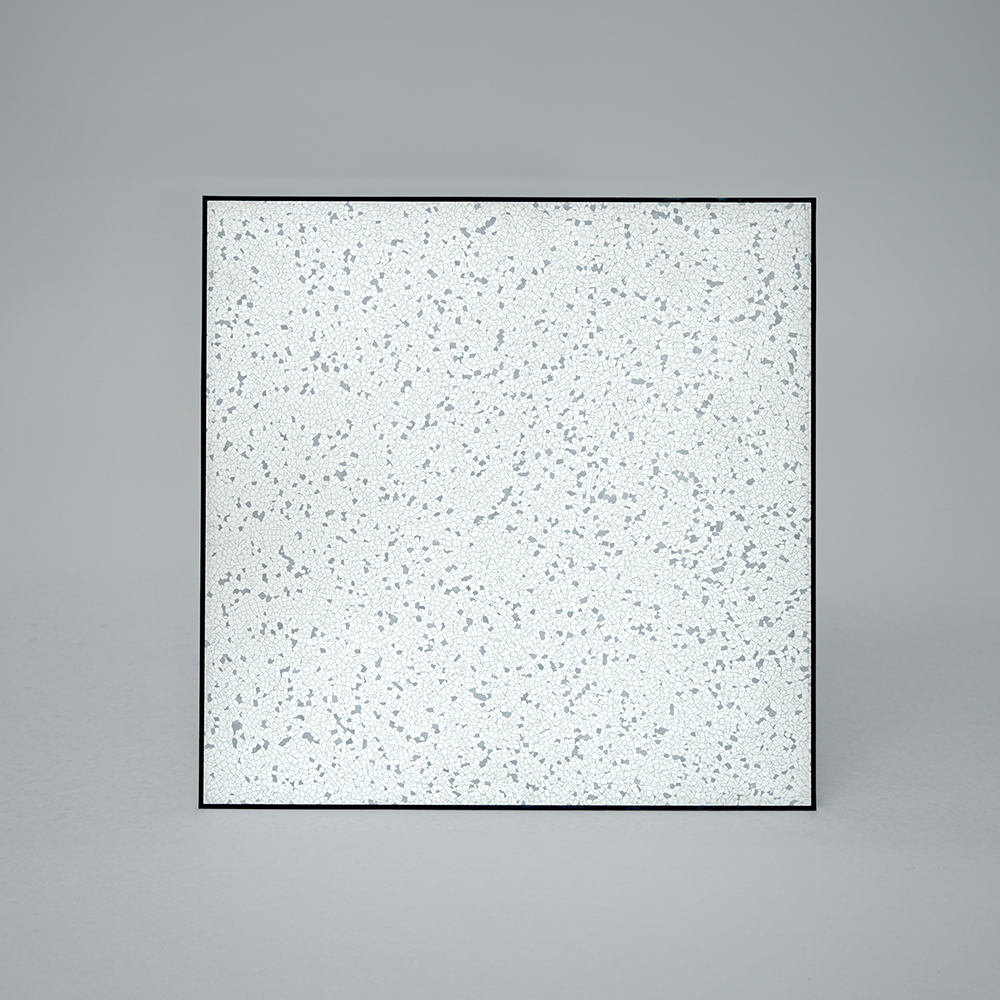

Panel Surface Finish

The topmost layer of a panel can be Bare, installed in its original state or with a carpet finish. High Pressure Laminate (HPL) is a common laminate finish. Other available finishes include ESD, PVC, and Vitrified.

Panel Grade

This is the technical coding given to a panel to determine what load-bearing capacities it can adhere to. Grade is typically referenced in lbf units. For example, 1000 Grade Panel refers to a Panel that can withstand 1000 lbf per sq inch.

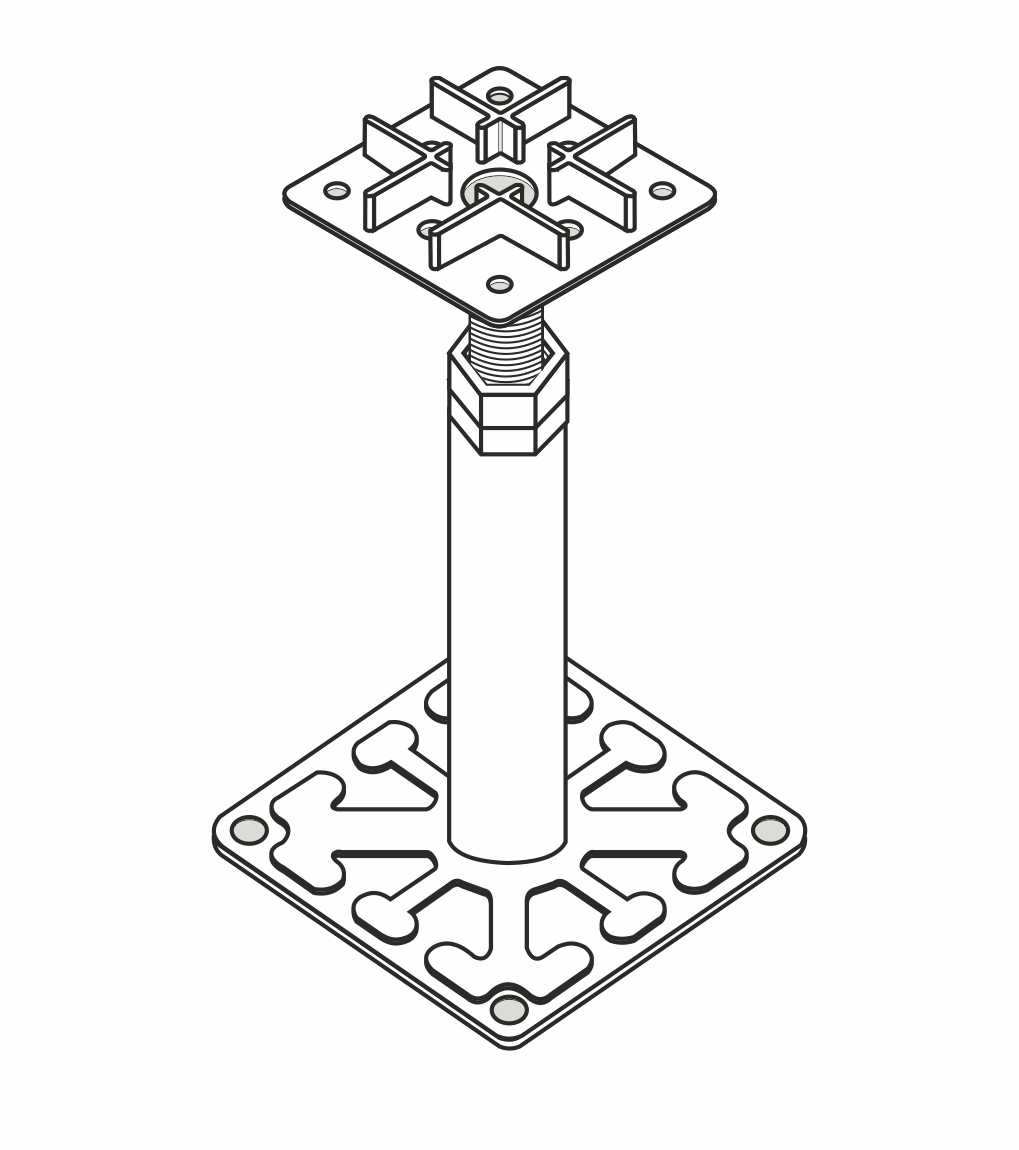

Pedestal

The pedestal, a vertical element of a raised floor, includes a Pedestal head on top of a pipe from a Pedestal base. Its dimensions vary to fit different floor heights and load-bearing capacities.

Stringer

This is the horizontal metal beam that forms a grid with each installed pedestal and provides additional lateral stability to the RAF panels.

- Why use RAFs?

- What makes our RAFs Systems Unique?

- What to Expect?

- Quick Installation: Designed for quick and easy installation and consequently minimizes costs and disruptions to your operations, ensuring a faster and smoother transition to your new workspace.

- Substantial Flexibility: Feature modular panels that can be easily reconfigured to accommodate changes in layout or infrastructure requirements, thereby maximizing the utility of your workspace.

- Seamless Integration with UFAD: Supports the integration of Underfloor Air Distribution (UFAD) – green technology that optimizes airflow management, enhancing indoor air quality and cooling efficiency.

- Optimized Cooling: In areas like Data Centers, Raised Access Floors itself optimize cooling efficiency and provide easy access to cabling, ensuring reliable performance and minimizing downtime.

- Versatile Applications: From corporate spaces to classrooms and auditoriums, raised access floors perfectly complement advanced technological needs, facilitating highly functional and comfortable environments.

- Patented Gusset Technology: Flexi’s RAF panels incorporate patented gusset technology, developed in-house, which enhances structural stability and load distribution at critical edges and corners. This ensures durability and safety, making our systems reliable and long-lasting.

- Wider Beam: At Flexi, we feature the widest beam and footprint area for pedestal heads, maximizing load distribution from the panel to the floor. This design ensures that our systems can handle heavy loads efficiently and securely.

- Universal Gap Requirement: Flexi’s RAF systems are designed to meet the required universal gap standards, ensuring compatibility and ease of installation across different environments and applications.

- Height Flexibility: At Flexi, our systems are dynamic, offering a floor height range from as low as 65mm up to 2000mm high. This flexibility allows for adaptation to various space requirements and architectural constraints, ensuring practicality and functionality in diverse settings.

- Aesthetics: At Flexi, our raised access floors combine technical precision with high aesthetic appeal through a variety of finishes, tailored to contemporary living needs and professional client preferences.

- Consultation: Our team conducts an initial consultation to understand your project requirements, budget, and timeline.

- Design and Planning: We develop customized RAF system designs tailored to your space, incorporating factors such as load requirements, underfloor service requirements such as airflow & cable management, as well as aesthetic preferences amongst other factors.

- Manufacturing and Testing: We conduct rigorous testing procedures to verify the performance and functionality of the manufactured RAF system to be delivered, ensuring compliance with industry standards.

- Dispatch and Installation: Once material is delivered, our experienced technicians install RAF panels, pedestals, and accessories according to the approved design plans, ensuring precision and attention to detail while adhering to best practices of installation as per industry norms.

- Handover and Support: Upon completion, we provide comprehensive handover documentation and ongoing support to address any questions or issues that may arise.

Why Choose FLEXI?

- Proven Expertise: As pioneers with over 30 years of industry experience, our team has a deep understanding of raised access floor systems, ensuring high-quality installation and support.

- Innovative Design: Our cutting-edge solutions enhance both aesthetics and functionality, aligning with modern workplace trends.

- Green Technology: Our products are IGBC and Green Pro certified for environmental sustainability, ensuring our products and services contributing to LEED points.

- Customer Satisfaction: Our tailored solutions and dedicated support throughout every stage of the project ensure that your specific needs are met, resulting in a seamless and satisfying experience.

FAQs

Consider load-bearing capacity, panel finishes, fire rating, seismic requirements, maintenance access, and sustainability features. For more details refer to Panel Selection guide.

Lifespan depends on materials and maintenance, but well-maintained systems can last 10 years or more, adapting to changing technology and space needs.

Raised Access Floors can be retrofitted into existing buildings. Consult with an installer to evaluate your space and determine the best approach.

Maintenance costs vary but generally include periodic cleaning, inspections, and occasional repairs or panel replacements.

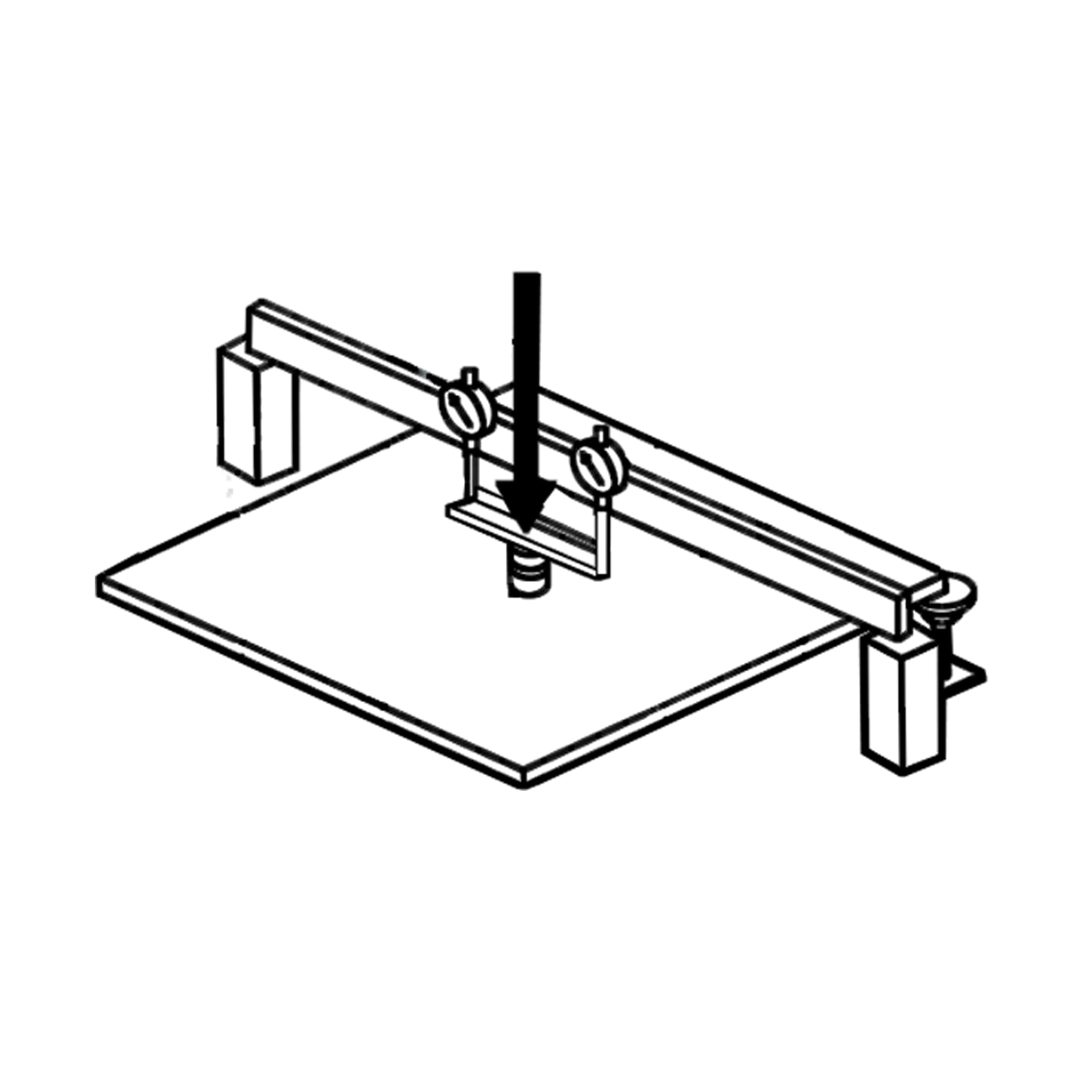

Installation involves:

- Preparing the subfloor.

- Setting up adjustable pedestals.

- Placing floor panels on the pedestals.

- Ensuring the system is level and secure.

Raised Access Floors can be customized in terms of panel material, finish, height, and load capacity to meet specific project requirements.

- Proper installation to avoid trip hazards.

- Ensuring the floor system meets fire safety regulations.

- Using anti-static panels in environments with sensitive electronic equipment.

They are commonly used in data centres, offices, command centres, and any environment that requires extensive cabling and air distribution.

Many Raised Access Floors are made from recyclable materials and can contribute to LEED certification points for green building projects.

Yes, Raised Access Floors are designed to support various load capacities. Ensure you select a system rated for the weight of the equipment it will support.