Airflow Management Solutions

What is Airflow Management?

Airflow Management refers to the strategic control and organization of airflow within a space, typically within workspaces and data centers. This involves optimizing the direction and distribution of air to enhance energy efficiency, maintain temperature uniformity, and improve overall environmental conditions for people and their surrounding equipment.

What are the typical components of AFM?

- Airflow management includes various products and services:

- Includes HAC, CAC, and containment:

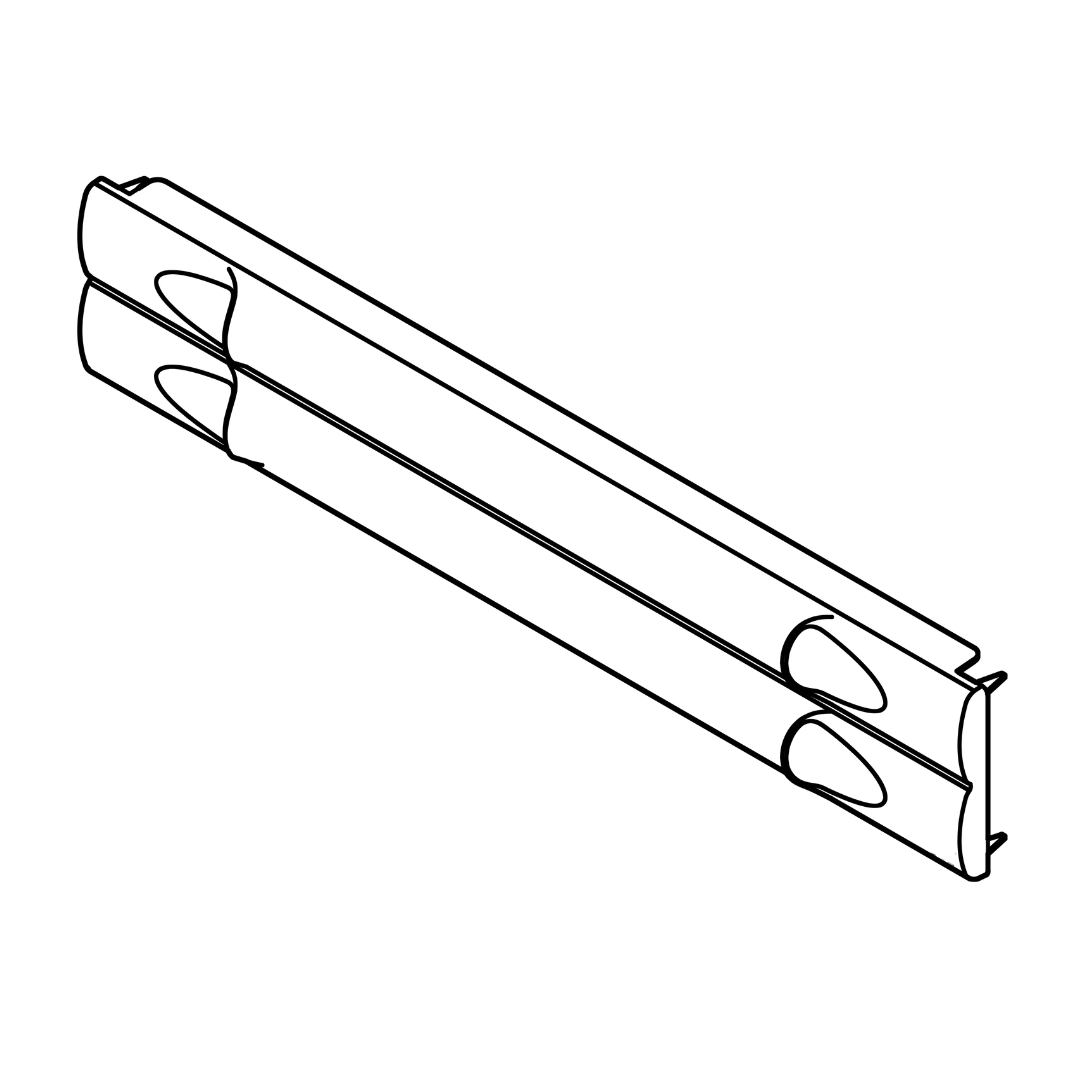

Blanking Panels

Are components used in data centers to cover unused rack spaces, preventing the recirculation of hot air and optimizing airflow management.

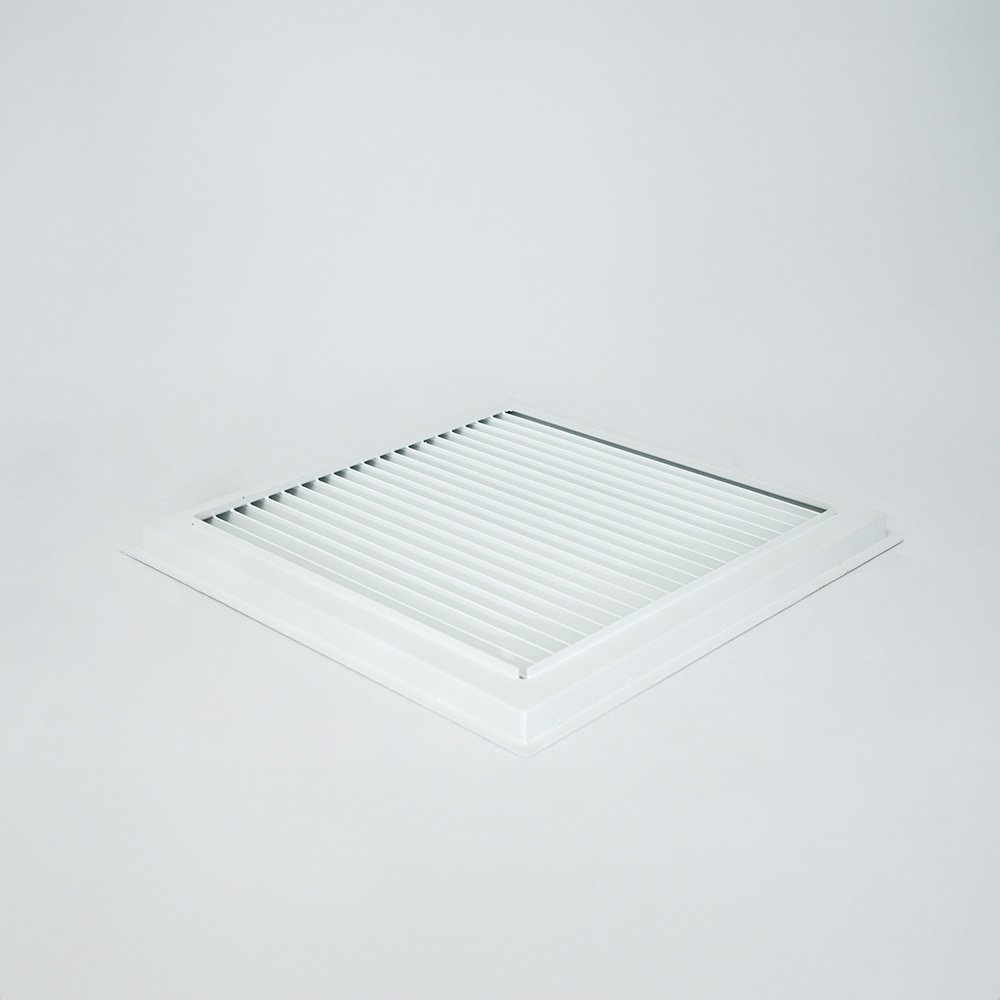

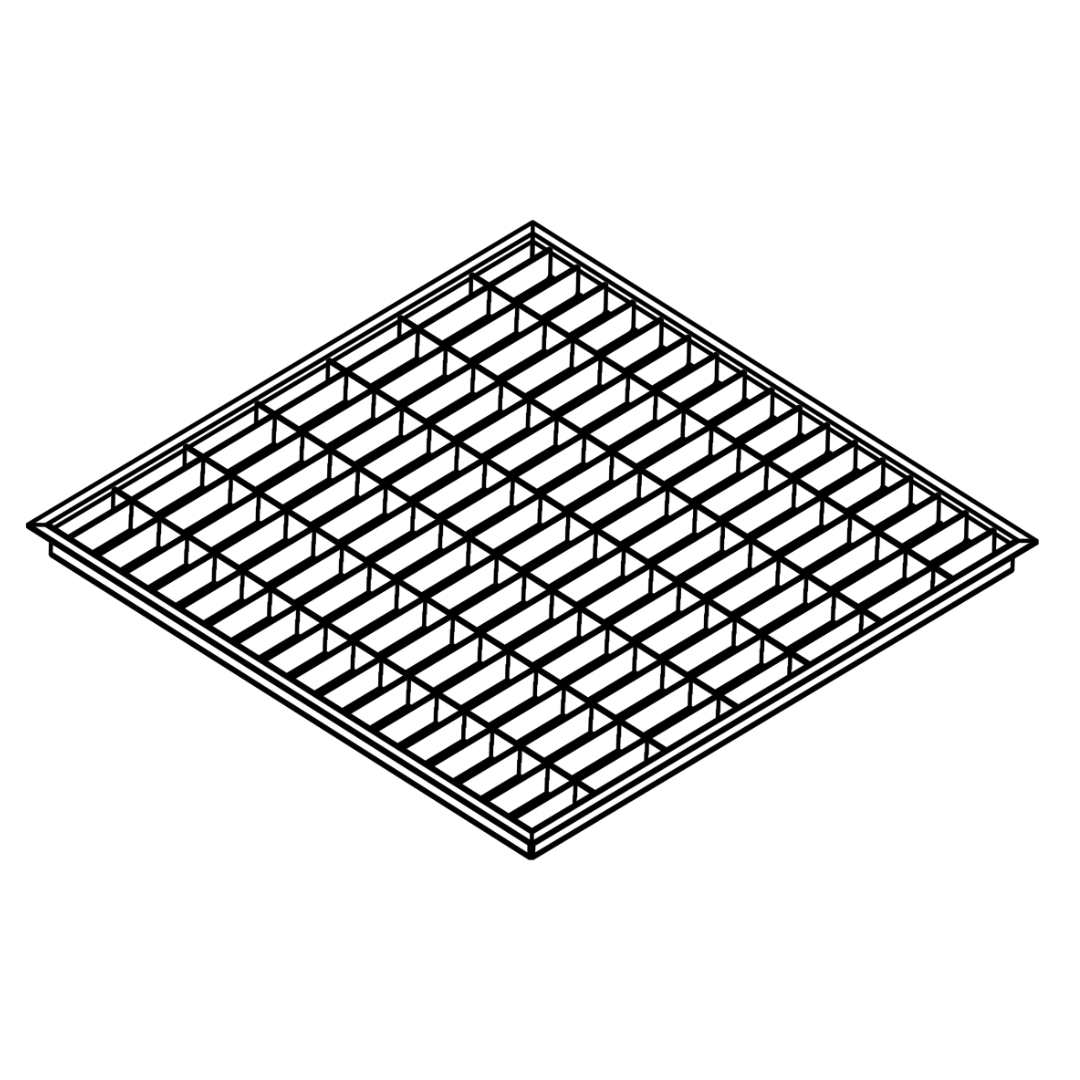

Airflow grilles

Are panels installed in data centers and other facilities to provide efficient movement of air, ensuring proper ventilation and thermal management within equipment racks and rooms. They typically feature a perforated surface to improve airflow rates.

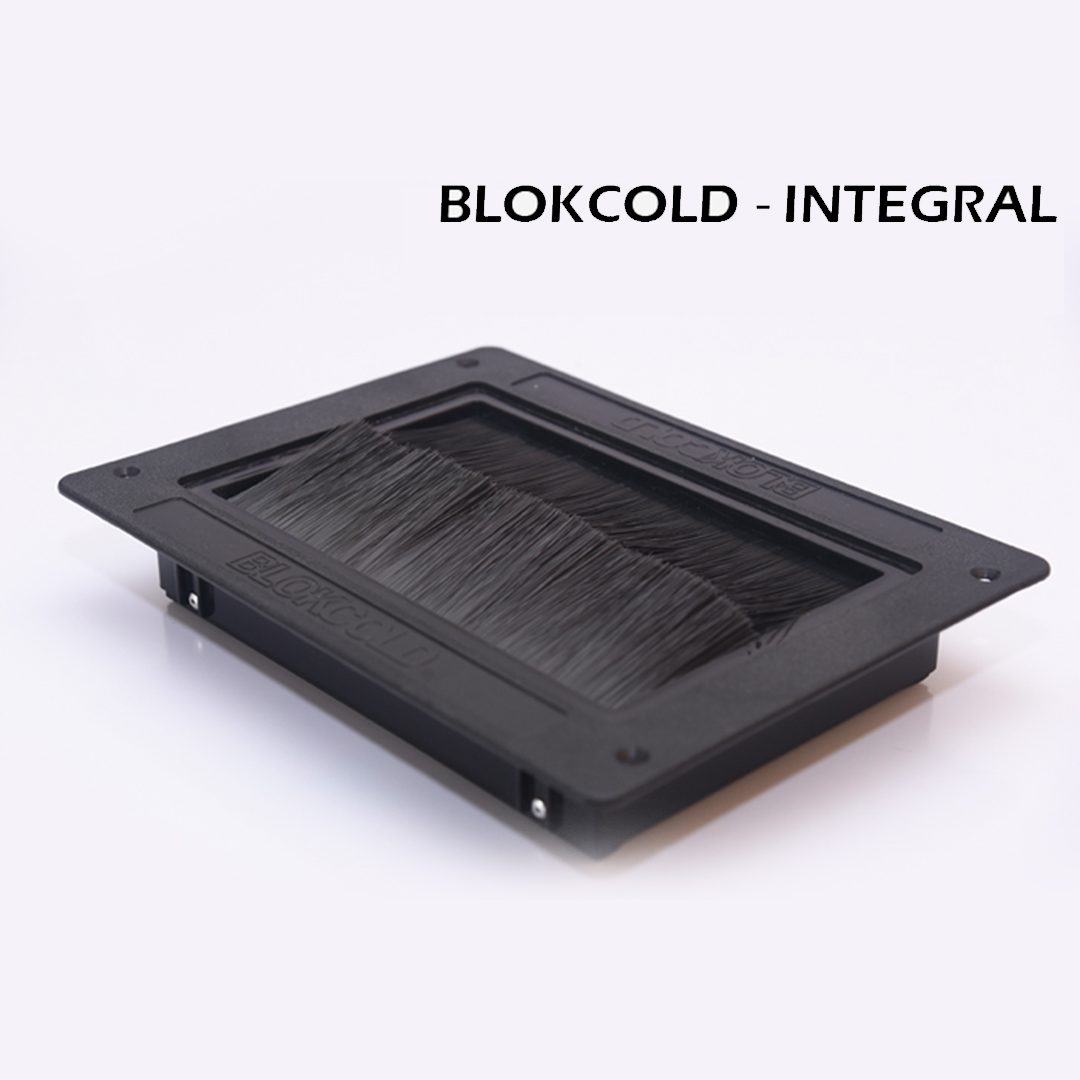

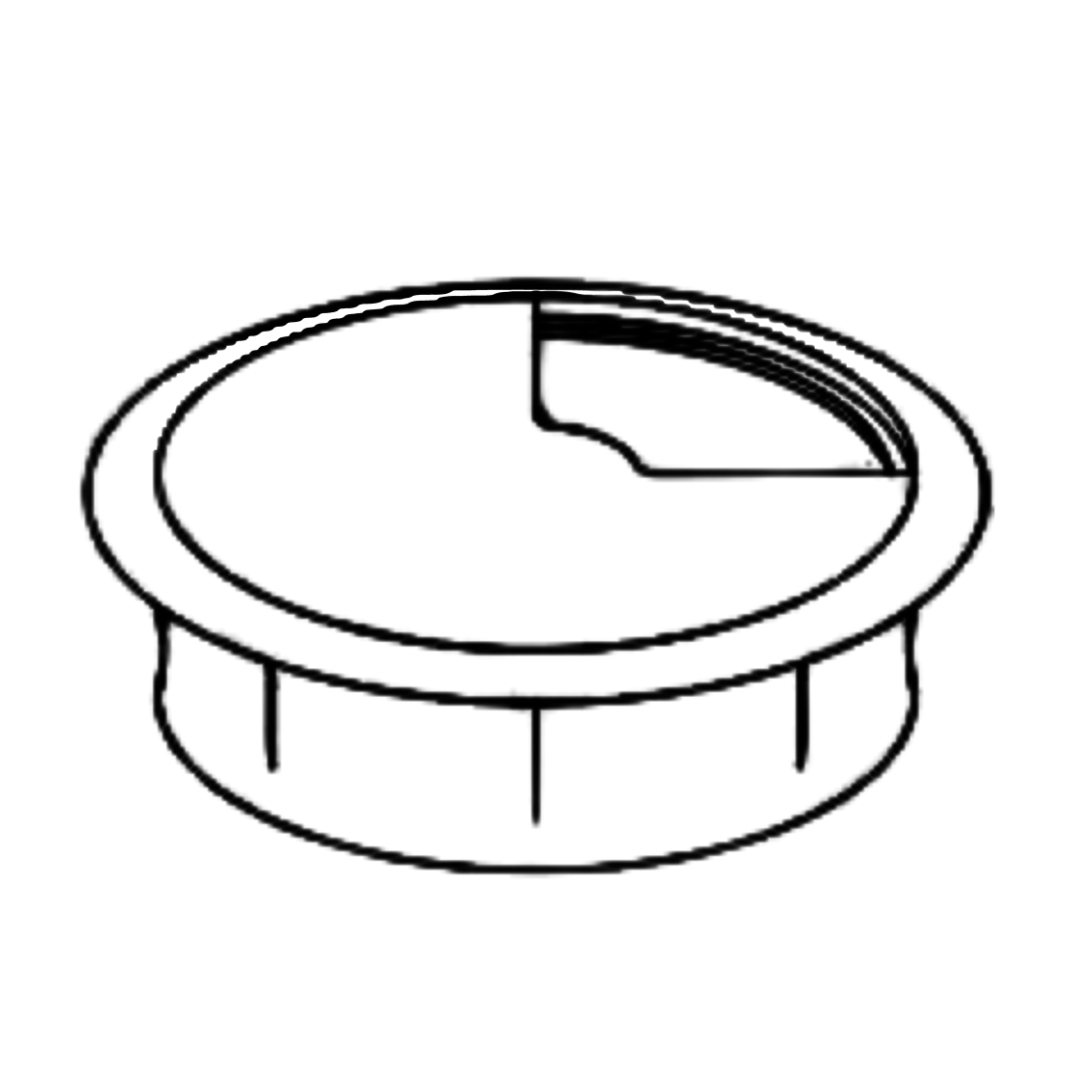

Grommets

In airflow management refers to seals or covers installed in data center raised floors to manage and optimize airflow. They help prevent air leakage, ensuring efficient cooling and energy usage within the facility.

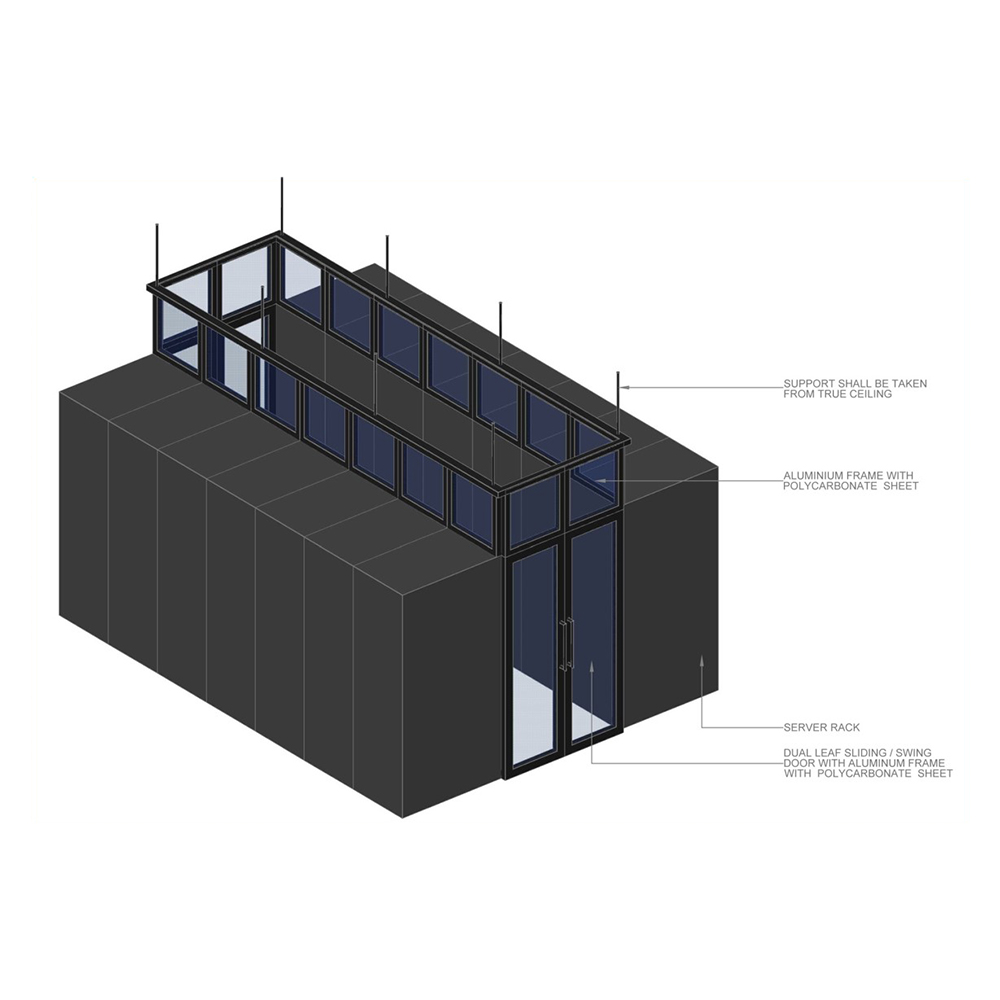

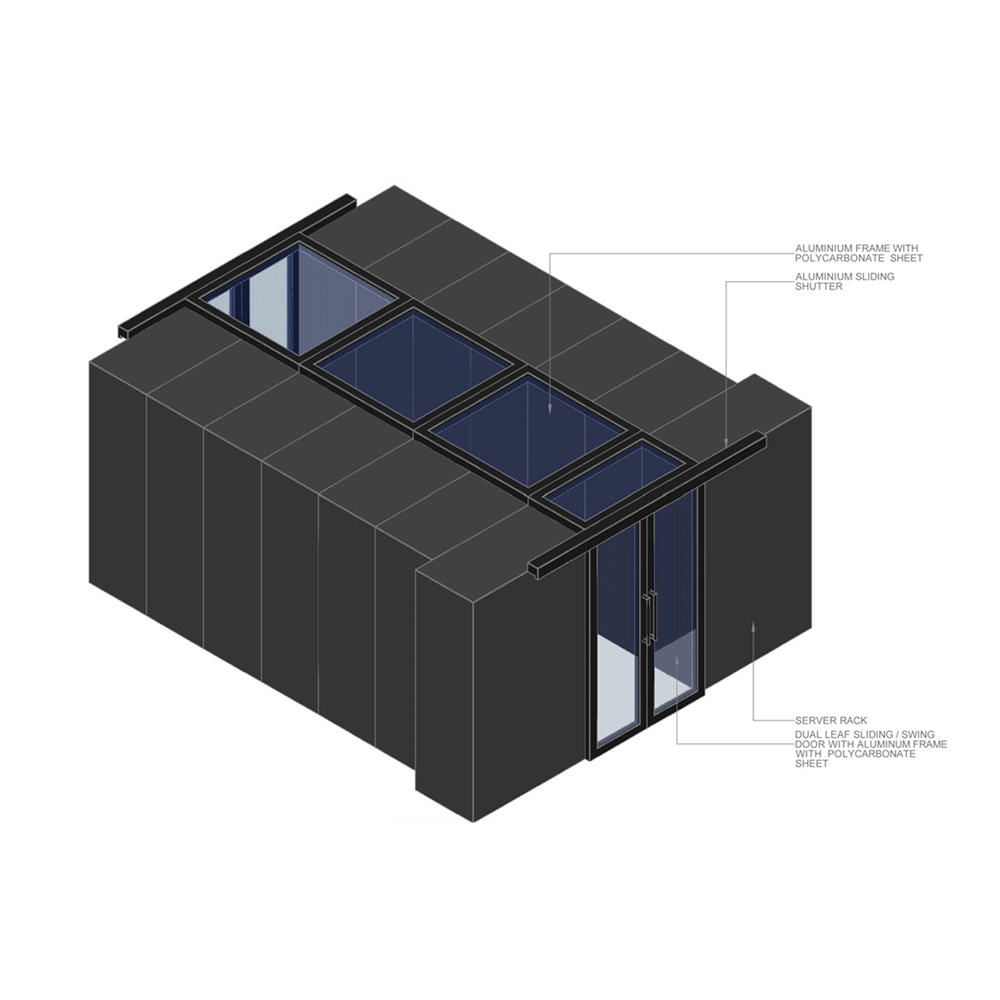

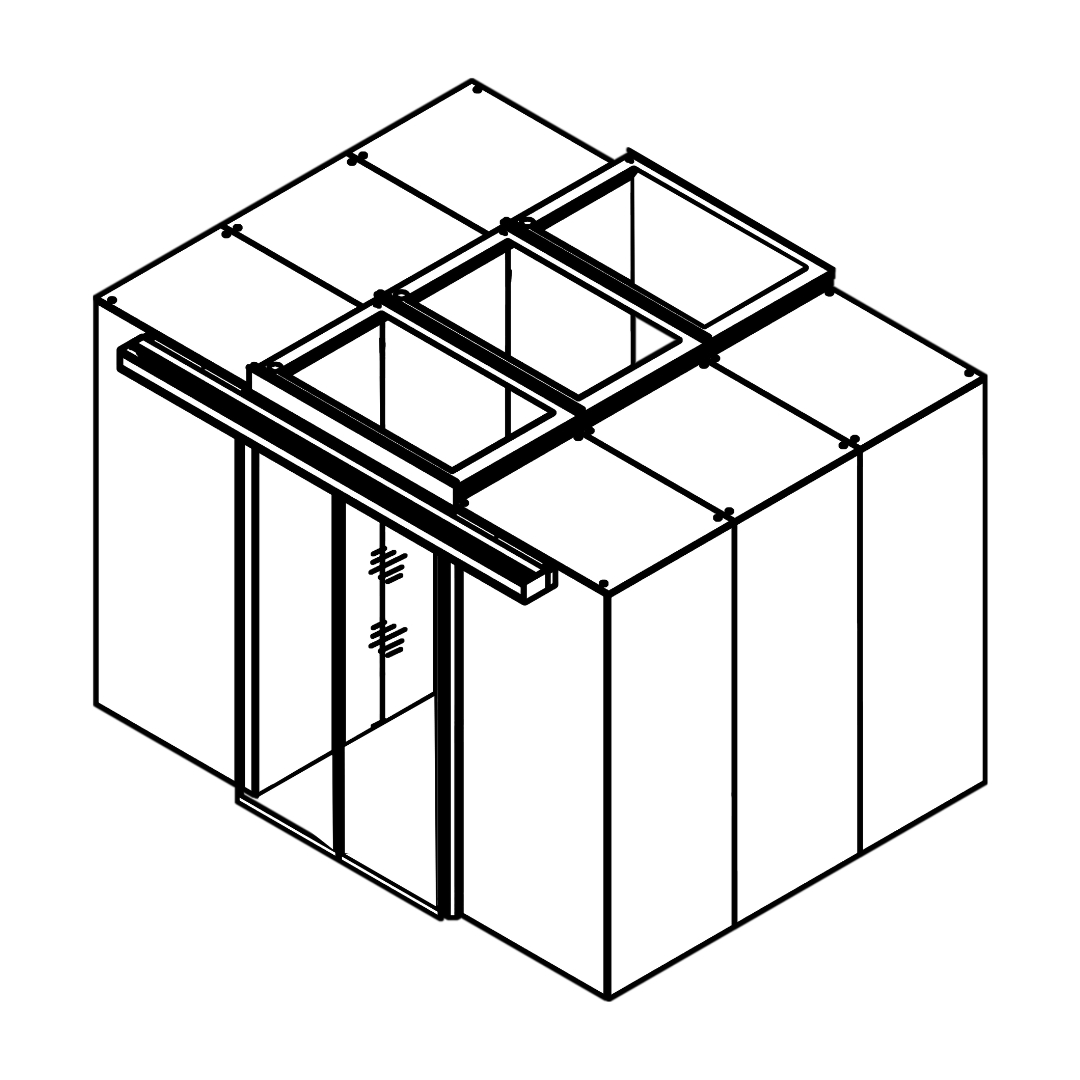

Containment

In airflow management refers to the practice of isolating and controlling airflow paths within a data center or other facility.

Containment Doors

Installed at aisle ends to seal off airflow paths, maximizing cooling efficiency in data centers.

Partitions

Walls or barriers separating cold and hot aisles to isolate airflow and optimize cooling effectiveness.

Roof Panels

Installed over aisle containment structures to seal airflow paths and direct airflow through IT equipment.

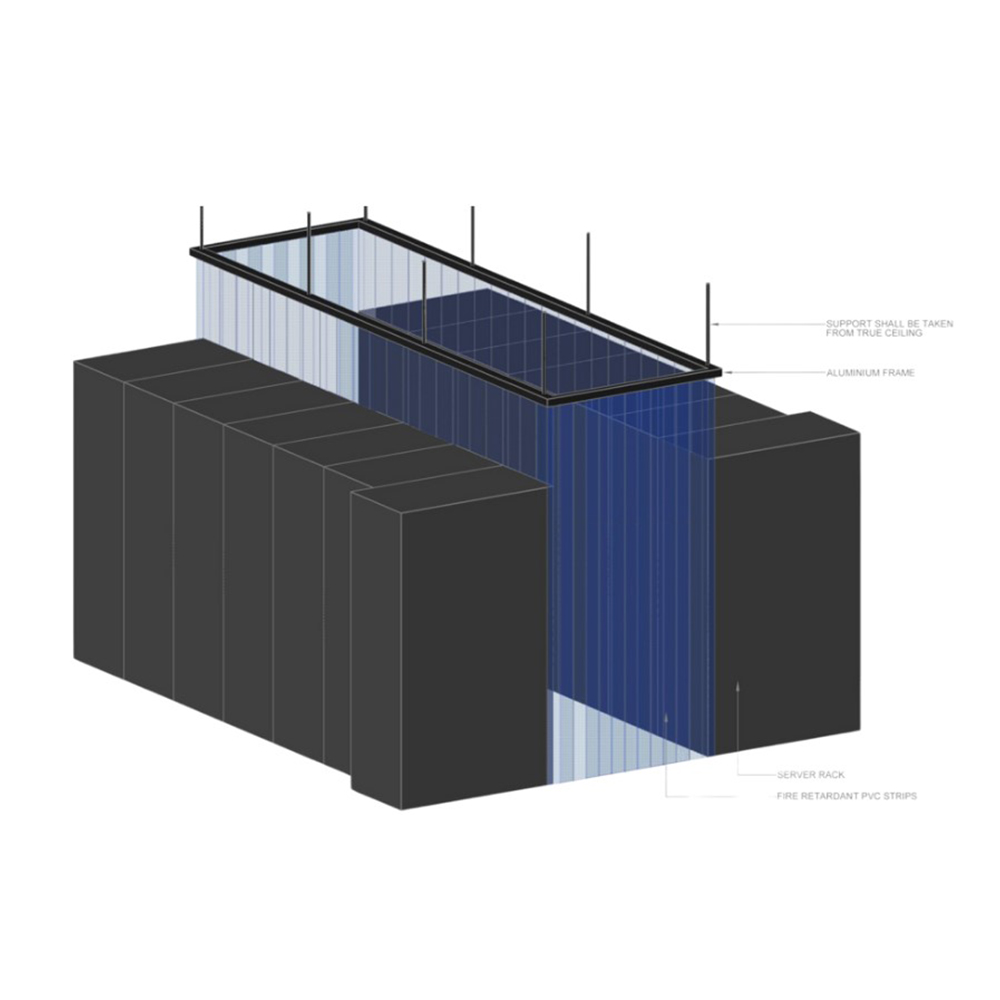

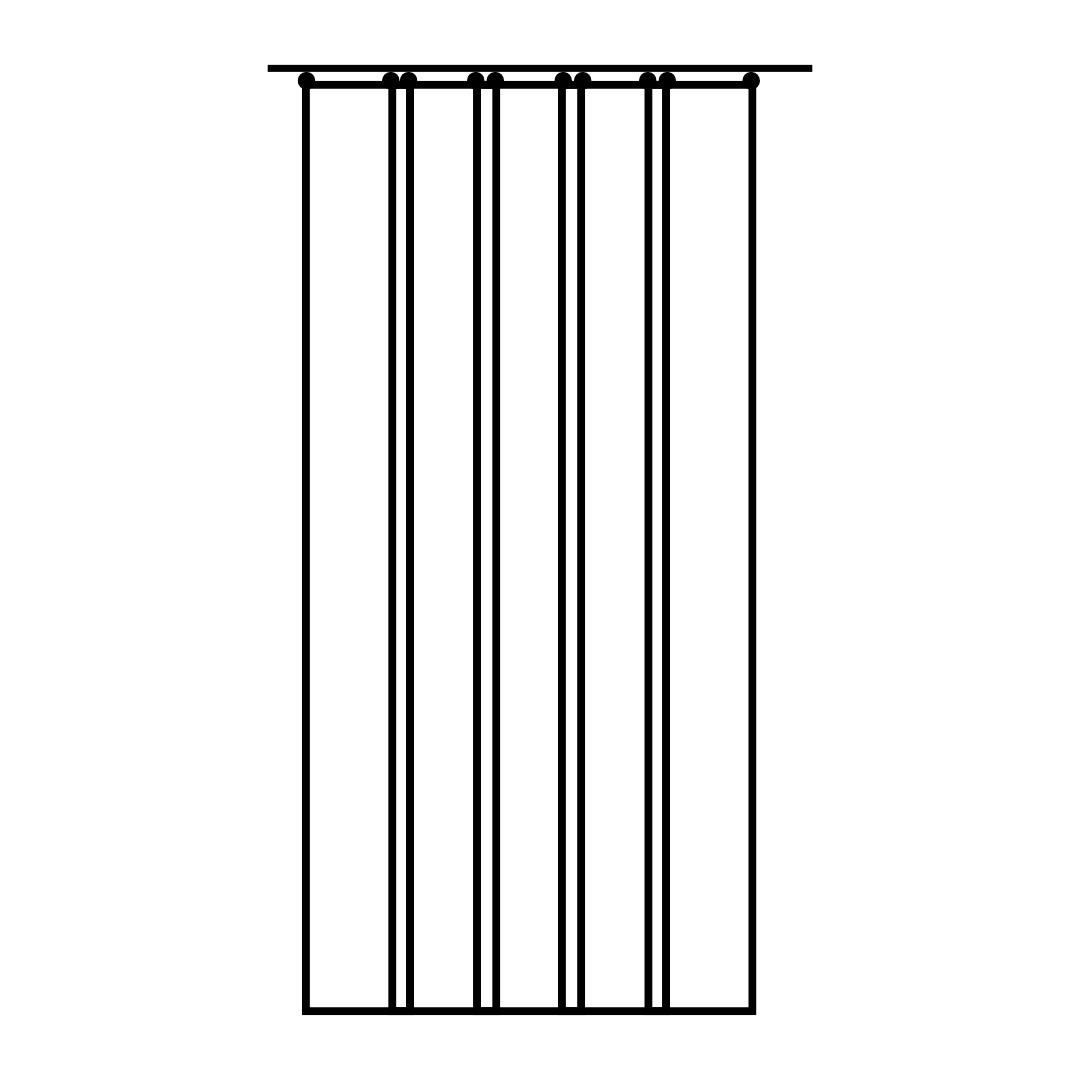

Curtains (Soft Aisle Containment)

These flexible barriers are crucial components of soft aisle containment systems, designed from fire-retardant materials to effectively segregate airflow between aisles while ensuring safety and flexibility in data center airflow management.

- Why deploy AFM Solutions?

- What makes our AFM Solutions Unique?

- What to Expect?

- Redundancy Planning: AFM solutions incorporate redundant components and fail-safe mechanisms to ensure continuous operation and reliability.

- Optimizing Temperatures: Maintain consistent temperatures and reduce hot spots, extending IT equipment life.

- Enhancing Data Center Efficiency: Improve overall efficiency, power usage effectiveness (PUE), and reduce energy costs.

- Maximizing Savings: Lower power consumption and operational expenses, providing a favorable return on investment.

- Flexible and Sustainable Solutions: Offer a flexible, reusable solution that optimizes real estate and reduces carbon footprint.

- Precision Manufacturing: Our in-house manufacturing capabilities ensure quality control, rapid prototyping, and efficient production schedules, guaranteeing timely delivery and adherence to project specifications.

- Optimized Airflow Design: We facilitate Computational Fluid Dynamics (CFD) analysis to optimize airflow and thermal comfort, ensuring design efficiency and compliance with environmental standards.

- End-to-End Support: Our dedicated support team provides end-to-end services including design consultation for system integration, installation, to even ongoing maintenance/ troubleshooting, ensuring optimal performance and energy efficiency of your facility.

- Advanced System Integrations: We embed the latest technology in our containment systems providing advanced digital controls and flexibility to integrate access with BMS systems. Also, our Blanking panels are designed to be snap-fit making installation easy and ‘tool-free’.

- Customizable Aesthetics: At Flexi, our solutions combine technical precision with high aesthetic appeal through a variety of configurations, tailored to client preferences.

- Project Initiation: We begin by consulting closely with our clients to understand their specific requirements and conduct thorough site assessments. This initial phase culminates in a detailed project proposal that outlines the scope, budget considerations, and agreed-upon timelines.

- Design and Planning: Our team utilizes the site survey and provided GA layout plans to meticulously develop comprehensive 3D design models, integrating client preferences, compliance standards, and the insights gained from our assessments.

- Manufacturing and Preparation: With in-house manufacturing capabilities, we ensure precision and quality control throughout the production of components prior to delivery at site.

- Installation and Commissioning: Following meticulous site preparation and phased installation of AFM systems, we focus on rigorous testing and fine-tuning to achieve optimal airflow and thermal management.

- Handover and Guidance: Upon successful commissioning, we provide thorough documentation, including design plans and operational manuals. We equip client personnel with the skills and knowledge needed to effectively operate and maintain the AFM systems.

- Ongoing Support and Maintenance: Beyond installation, we offer proactive maintenance services to uphold optimal system performance. Our responsive troubleshooting and support services ensure minimal downtime, while our commitment to recommending and implementing system upgrades ensures long-term operational efficiency and client satisfaction.

So Why Choose FLEXI?

- Proven Expertise: Our strategic partnership with Upsite Technologies enhances our AFM solutions with industry-leading innovations and expertise, ensuring optimized cooling efficiency and enhanced operational reliability across all projects.

- Versatile Project Scope: We undertake AFM projects of any scale, from single-aisle configurations to large-scale deployments spanning multiple sites, floors, and square footage

- Cutting-Edge Technology Integration: We integrate the latest technological advancements into our solutions, including features like automatic door closers and retractable roof panels, enhancing efficiency and functionality in airflow management systems.

- Customer Satisfaction: Our tailored solutions and dedicated support throughout every stage of the project ensure that your specific needs are met, resulting in a seamless and satisfying experience.

FAQs

CFD modeling can be useful, but it should be combined with a cooling systems tune-up to recover capacity and reduce hotspots. It can’t replace the essential work of identifying and fixing on-site problems. Accurate CFD models require extensive on-site measurements; otherwise, predictions may differ from actual conditions.

Place perforated tiles in front of the rack in the cold aisle to cool the air intake side of the servers.

Yes, arranging racks to face the same direction can cause cooling issues, as the hot air exhaust from one row becomes the intake for the next. This setup can lead to premature and unexplained equipment failures.

Many data centers experience increasing heat load density due to bypass airflow and the high performance of more compact IT equipment. Bypass airflow, where up to 70% of cooling is wasted due to un-engineered mixing of hot and cold air, leads to inefficient cooling and hot spots. Additionally, as IT equipment becomes smaller but more powerful, it generates more heat in a reduced space, exacerbating cooling challenges

Yes, our company provides comprehensive shop drawings for both Cold Aisle and Hot Aisle containment solutions.

Yes, our AFM containment solutions include advanced automation features such as automatic door closers and retractable roof panels to enhance operational efficiency and convenience.

Yes, our systems are designed with manual overrides to ensure that you can maintain control and access in the event of a power outage.

Using grommets is crucial for maintaining proper airflow and cooling efficiency. They seal gaps where cables pass through the raised floor, preventing bypass air from escaping.

Yes, containment solutions can be customized to fit the specific layout and requirements of existing facilities. Options include adjustable panels, modular systems, and flexible barriers that can be tailored to different room configurations.

Our snap-fit blanking panels are an exclusive capability of our company. They are designed for easy installation and removal without the need for tooling, simplifying maintenance and enhancing airflow management.