Manufacturing

Our Facility

FLEXI’s state-of-the-art facility is strategically located in the heart of Gujarat’s fastest-growing city, spanning over 100,000 sq. ft. Our facility is equipped to handle a range of products, including Raised Access Floors (RAF) and Underfloor Air Distribution (UFAD) systems, as well as Airflow Management (AFM) components and boasts several key strengths:

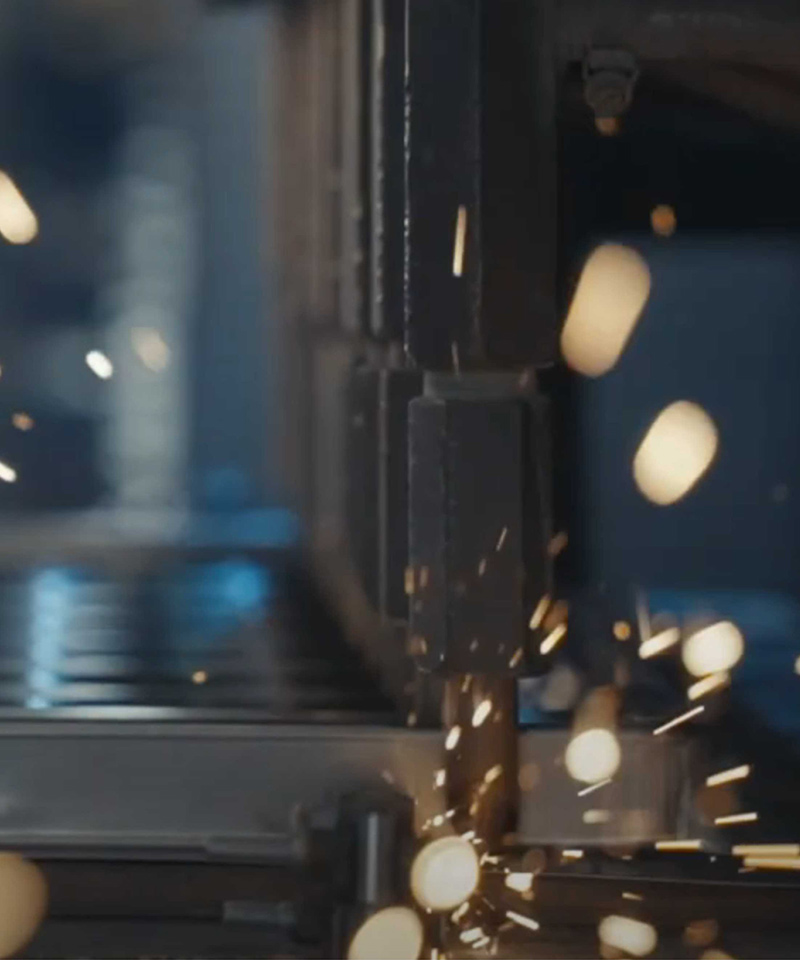

- Multi-Spindle Resistance Welding: Provides precise and durable panel construction, enhancing structural integrity.

- High Precision, Multi-Axis Laser Cutting Technology: Used for crafting interlocking stringers with exacting standards, ensuring seamless integration. As well as for our AFM grilles.

- In-House Understructure Manufacturing: As the only company in India with this capability, it ensures seamless integration and superior performance of our systems.

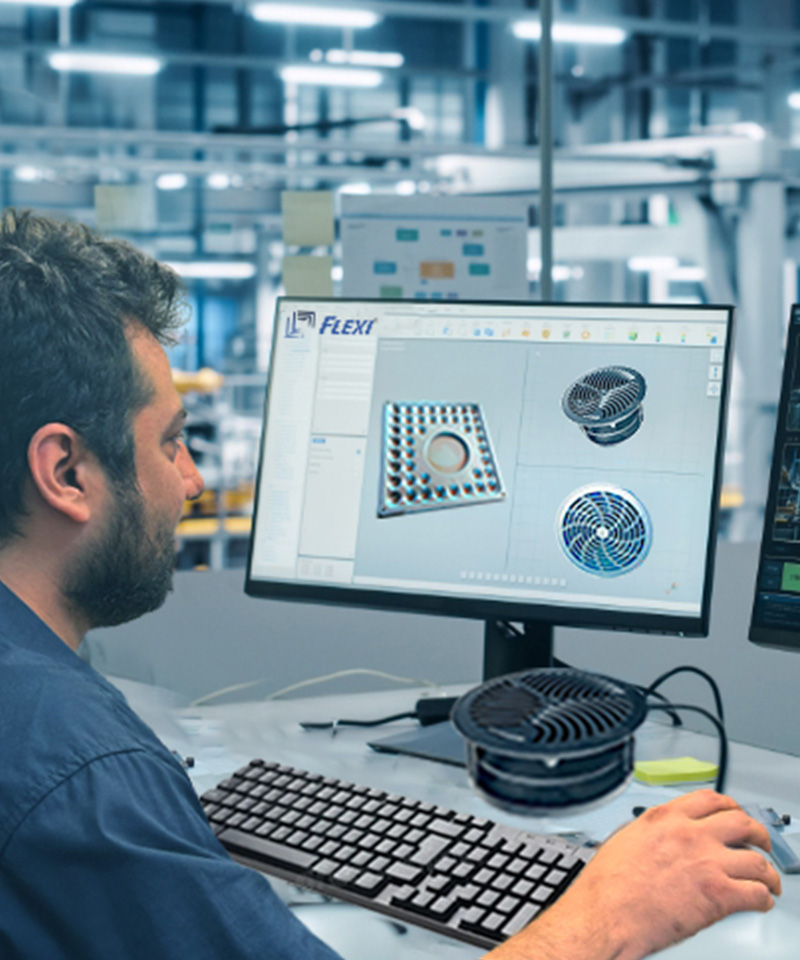

Research and Development

Our commitment to continuous Research and Development sets us apart in the OEM industry and drives our growth. We actively send team members to project sites for firsthand understanding of application needs, integrating new technologies based on diverse feedback from customers, users, and installers. This direct engagement fuels our innovation and development process.

- Gusseted Technology: This patented technology enhances structural stability and load distribution at critical edges and corners, ensuring the durability and safety of our RAF panels.

- Vitrified Bonding: A patented process that improves the bonding strength and longevity of our panels, providing enhanced performance and resistance to wear.

- Lightweight Concrete Infill Recipe: Our unique recipe for lightweight concrete infill reduces panel weight while maintaining strength, contributing to ease of installation and overall efficiency.

- Specialized Forming Process: Instead of traditional panel cuts, we use a specialized panel forming process to integrate seamlessly with UFAD diffusers. This is an exclusive capability that sets us apart not just in India but globally.

Testing and Quality Assurance

At FLEXI, quality is central to our manufacturing process. Our comprehensive testing and quality assurance protocols include:

- Raw Material Testing: Ensures incoming materials meet quality standards before production.

- Daily Quality Testing: Conducted in-house to monitor product quality at every fabrication stage..

- Regular Calibration: Equipment and machinery calibrated under NABL India’s norms for accuracy and reliability.

- Third-Party Validation: Products validated by Civil Aid Technologies Bangalore and Steadrant Technologies, affiliated with Bureau Veritas France.

- Additional Testing: Conducted at TUV PSB facilities in Singapore to ensure compliance with the highest international standards.

- International Standards Compliance:

o MasterSpecs (USA)

o BSEN (Europe)

o CISCA Testing Standards

o MOBPF2PS (UK)

Our commitment to quality spans the entire chain of operations, from design and procurement to manufacturing, distribution, installation, and after-sales service. Supported by experienced staff, we ensure efficient solutions and smooth, successful project outcomes.